FAQs

Laser Diode Module Comparison — Visible to SWIR

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

450

nm Laser (Blue): A visible blue wavelength

producing a sharp, high-contrast beam. Blue lasers are highly visible and

effective for projection and fluorescence excitation.

Typical

Applications: Laser projectors, stage lighting, fluorescence

excitation, biomedical instrumentation, industrial alignment, and material

processing.

520

nm Laser (Green): The most visible wavelength to

the human eye, appearing much brighter than red or blue at the same power.

Provides a sharp, round dot with excellent beam quality, ideal for outdoor and

long-distance visibility.

Typical

Applications: Surveying, construction alignment, laser

pointers, stage displays, and precision measurement systems.

635

nm Laser (Red–Orange): A bright visible red laser with

high eye sensitivity compared to 650 nm. Provides superior visibility under

strong ambient light.

Typical

Applications: Laser pointers, leveling tools, alignment

systems, medical aiming beams, and display devices.

650

nm Laser (Deep Red): A widely available and

cost-effective red wavelength. Slightly less visible than 635 nm but popular

due to diode affordability and durability.

Typical

Applications: Barcode scanners, laser pointers, industrial

alignment, consumer electronics (DVD/CD players).

780

nm Laser (Near-IR / Deep Red): On the edge

of visible and NIR spectrum, appears as a faint deep red glow. Economical and

compatible with many optical systems.

Typical

Applications: Optical storage (CD/DVD drives), spectroscopy,

medical diagnostics, and alignment where partial visibility is acceptable.

850

nm Laser (Near-IR): The most popular NIR wavelength.

Invisible to the eye but highly compatible with silicon-based detectors, making

it ideal for IR cameras and sensors.

Typical

Applications: Night vision illumination, eye tracking,

industrial sensing, biometric authentication, medical imaging devices.

940

nm Laser (Near-IR, Deep): Fully invisible to the human

eye. Provides reduced interference with visible-light imaging systems and

enhanced stealth operation.

Typical

Applications: Security and surveillance, 3D sensing, gesture

recognition, consumer electronics (smartphones, AR/VR), covert eye-safe

illumination.

Typical Applications: Wafer and material inspection, spectroscopy, industrial sensing, and biomedical imaging.

The laser modules are critical components for industrial/technical applications. They are mounted inside machine and could emit more precise laser beam, ideal for industrial applications. Therefore, Quarton's laser module is the preference if you need to customize the unique specifications or work for high quality.

All of our laser modules are designed to

accept only specified certain range amount of voltage in order to operate the

laser, the power output of the laser module will not emit beyond the power

within the specification due to excessive voltage. The Laser output power must

be stable especially in safety reason.

1. The laser modules will emit heat while

they are working, high working temperature is frequently the reason for laser

failure, more than that, it may cause the laser spot size or laser line width

will be larger. Operate the laser module at proper temperature range can extend

its lifetime, each laser module has its specified temperature range. Besides,

you could add a heatsink to laser module in order to heat radiation.

2. Some series of laser module housing is

an electrical positive surface, it is imperative that contact between the laser

module and the machine be avoided. This is to prevent damage from the machine

electrical leakage.

3. Please don't pull vigorously the electrical leads. The two leads are the positive (red) and negative (black), be used for operating power.

Fan angle is the angle spread of laser beam, it will affect the line length of laser line (such as line or crosshairs) at a particular distance. The fan angle is bigger, the laser line is longer at certain distance. Length of laser line is proportional to the distance from laser module to projection surface.

Our dot laser

modules have ellipse dot and circular dot to be select, and there are line or

crosshairs laser modules.

The glass lens

can be used on relatively high power of laser modules and it could endure the

more temperature changes. It also has higher light transmission and better

scratch resistance.

The plastic lens is an economic and durability proposal. It is lighter than glass and can be designed for customized request easily, it means compatible with many laser module. For indoor application, it works almost same as glass lens. However out of room temperature range, plastic lens will cause defocus a little and laser dot could be fuzzy.

According to FDA requirements:

POLICY: In keeping with this recognition of a hazard and the advice given, the Center for Devices and Radiological Health (CDRH) will object to any intentional exposure of the public to hazardous levels (1.e., greater than Class I levels) of laser or collateral radiation (light) from this type of equipment. Further, the CDRH will object to any instructions or promotion of Class II or IIIa demonstration laser products (projectors, scanners, shows, etc.) that do not adequately warn the user to prevent such exposure.

Class I audience exposure levels.

Only Class I levels of laser radiation have no known hazard and these are the only exposure levels that are considered safe for direct exposure of people. Exposure of the audience to levels in excess of the Class I limits is not to be promoted or encouraged in any way.

Class II warning:

CAUTION Laser Radiation (or Light)

Do Not Stare Into Beam

Class IIIa warning: DANGER Laser Radiation (or Light)

Avoid Direct Eye Exposure

These levels are hazardous to the eyes. No direct or reflected beams may be directed into audience areas or used to scan the audience in any way. A projector certified as Class II or IIIa cannot be used for audience scanning unless the projector is equipped with an adequate scanning safeguard which will prevent scanning above the Class I limits and adequate user instructions for achieving the Class I levels are provided.

Class IIIb hand-held lasers are too dangerous for use as pointers or amusement articles. Furthermore, promotion of Class IIIb or IEC Class 3B products for pointing or amusement violates FDA requirements and United States law. Manufacturers of such products may be required to repair, replace, or refund the purchase price of violative products distributed in the U.S. These products are also subject to detention and seizure by the U.S. Customs and Border Protection when imported.

Irresponsible use of more powerful laser pointers poses a significant risk of injury to the people exposed. Persons who misuse or irresponsibly use lasers are open to personal liability and prosecution.

Reference: https://www.fda.gov/radiation-emitting-products/laser-products-and-instruments/important-information-laser-pointer-manufacturers

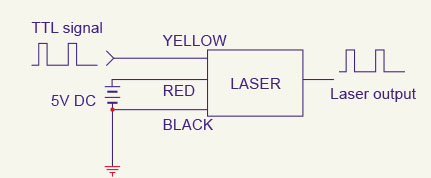

Our most laser modules are continuous wave

(CW) and can't be modulated. Therefore, we had additionally designed the laser

modules with modulation function, you could review our TTL modulation laser

modules on various category.

TTL Operation Function Diagram:

TTL Level:

Class IIIa or IEC Class 3R lasers can be dangerous. Class IIIa lasers can cause temporary visual effects such as flash blinding, which could distract or startle the person exposed. The risk of injury is very small when Class IIIa pointers are used responsibly because natural body motion of a person holding the pointer or motion of a person who might be exposed makes it difficult to expose the eyes for a long period of time. People also have a natural aversion to bright lights and are likely to close their eyes and turn their heads if exposed.